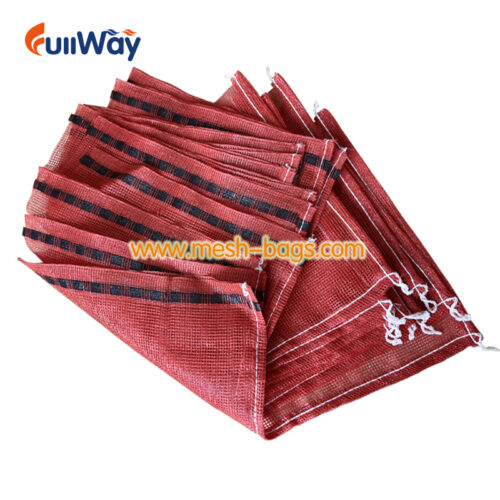

Sacos de batata de malha

Sacos de batata de malha

Sacos de batata de malha

Sacos de batata de malha

Saco de malha ecológico excelente de tamanho personalizado por atacado

Sacos de batata de malha

Saco Rachel de malha PP por atacado para cebola, batata, legumes e frutas

Onion mesh bags wholesale size

56x85cm / 52x80cm / 55x87cm (custom)

(If you have size requirements, you can customize it. If you want to wholesale onion bags in bulk, onion bags can be individually customised in terms of size, colour, shape etc.)

Detailed parameters for onion bags wholesale

1. Minimum order quantity and price

The minimum order quantity for ordering ordinary onion bags is 100,000 When the order quantity is 100000-200000, the price of the onion bag is 15$ When the order quantity is more than 200,000, you can call us to negotiate. If you want to customize the onion bag: Customized logo (minimum order quantity: 200,000 pieces) Customized packaging (minimum order quantity: 200,000 pieces) Graphic customization (minimum order quantity: 200,000 pieces)2. Custom

Fullway's accepts customized onion bags in bulk. This includes polypropylene mesh bags that can be custom sized or adjust the density of the holes in the mesh vegetable bags to suit your needs. Most importantly, we can customize polypropylene mesh bags with onion bag colors. We have professionally printed Onion sack in four colors for you to choose from. Fullway's has a professional mesh net bags design team. Can print Your corporate logo on mesh net bags to showcase your brand image and increase brand awareness. Polypropylene mesh bags are available in 50g/65g weights, and you can also customize thicker or slimmer onion bags in bulk. And Fullway's onion bags are made from eco-friendly materials, making them safer and more environmentally friendly to use. Onion bags are also available at high and low prices, so you can choose wisely according to your situation. (If you need mesh bags wholesale, you can also call the staff and ask for them). The supply capacity of mesh bags wholesale: 100,000 pieces/day. Fullway has its polypropylene mesh bags production factory. He has hundreds of workers and machines to produce large quantities of onion mesh bags quickly every day. If you need a large amount of mesh net bags in a short period, fullway can meet your needs.Onion bags wholesale material

The primary materials of green onion mesh net bags are Polypropylene and polyethylene. Chemical composition.

PP is a non-toxic, odorless, and tasteless milky white highly crystalline polymer. Its density is 0.90--"0.91g/cm3. It is one of the lightest varieties of all plastics at present. It is particularly stable to water, so it has a good waterproof effect. The surface of the packaging bag is made of it. It has good gloss and uses it widely in general daily necessities products. PE is a thermoplastic resin made by polymerization of ethylene. PE is odorless and non-toxic. It feels like a candle when touched by a hand. It has excellent resistance to Low-temperature performance, good chemical stability, resistance to most acid and alkali corrosion. So it is widely used in commodity packaging.Chemical properties.

PP has high crystallinity and stable structure, so it has excellent mechanical properties. Temperature and loading rate has a significant influence on the toughness of PP. PP's anti-bending performance is fantastic, and the products made with it can be bent hundreds of times at room temperature without being damaged. But at room temperature and low temperature, due to its high molecular structure regularity, the impact strength is lacking. Therefore, the finished products of PP are not suitable for storage at low temperatures. However, PP has a good heat resistance and can sterilize the products at a temperature above 100°C. And PP does not deform at 150°C under the condition of no external force. But its embrittlement temperature is -35℃, which means that PP will become embrittlement when it is lower than -35℃, so the cold resistance of PP is not as good as PE.A estabilidade química do polipropileno é excelente.

In addition to its poor resistance to acidification, concentrated sulfuric acid, and concentrated nitric acid, it has relatively stable reactions with other chemical reagents. Simultaneously, its chemical stability will increase with crystallinity, so Polypropylene is suitable for making various chemical pipes and onion bags bulk. Polyethene is a thermoplastic with the most significant output and a wide range of uses among plastics. It is polymerized by ethylene and can process by general thermoplastic molding methods. Polyethylene can divide into three categories: high-density polyethylene, low-density polyethylene, and linear low-density polyethylene. PE has excellent chemical stability. It is not affected by various chemical substances such as hydrochloric acid, hydrofluoric acid, potassium hydroxide, etc., at room temperature. But these chemicals do not include nitric acid and sulfuric acid because these two chemicals have a robust damaging effect on PE. Polyethylene is prone to degradation under ultraviolet rays' action, so onion bags bulk cannot expose to the sun for a long time.Uses of PE and PP

O polietileno tem um preço baixo e é fácil de moldar, pelo que tem uma vasta gama de aplicações.

It is widely used in commodity packaging; high-density polyethylene is mainly used for packaging films and bottles and other commodities; the primary use of low-density polyethylene is packaging film and agricultural film; linear low-density polyethylene use especially for Films, pipes, wires, and cables. Can directly send the scraps, defective products, and other waste materials generated in the production to the extruder for crushing and compression. Its recycling process is relatively simple. But if the waste plastic comes from the chemical industry, electrical industry, food and consumer goods industry, etc. Then these discarded packages have been contaminated and can no longer be recycled. Also, many harmful substances will appear in the recycling process, which is not environmentally friendly.Em comparação com o polietileno e o polipropileno, o polipropileno é mais amigo do ambiente.

PE can be recycled and will release no harmful substances during the recycling process. The decomposition rate of PE is also faster, which only takes 20 to 30 years, while the decomposition of PP and some other plastics takes more than 500 years. In recent years, extreme weather has been persistent both in my country and in the world. Air pollution is also severe. Many people have already realized the problem of environmental protection. Therefore, whether in daily life or industrial production, energy-saving and environmentally-friendly materials are required. Polypropylene is a new material that is green, energy-saving, and environmentally friendly. O surgimento e a utilização do polipropileno já existem há muito tempo e a sua tecnologia de produção também foi optimizada em grande medida. Atualmente, tem sido aplicado com sucesso na produção de sacos de cebola. Em comparação com os plásticos comuns, o polipropileno tem duas vantagens significativas: Em primeiro lugar, a sua dureza é muito maior do que a dos plásticos, e a sua resistência à corrosão e capacidade de exposição são relativamente fortes, e não é acessível ao envelhecimento. Outra vantagem é o facto de o polipropileno não conter quaisquer toxinas e não ter odor. É um material não tóxico e inofensivo para o corpo humano. Por conseguinte, o polipropileno é um novo material ecológico, que poupa energia e é amigo do ambiente.Comparison of the polypropylene mesh bags and paper box

With the successful development of companies and the fierce competition between them, customers demand more from polypropylene mesh bags. Nowadays, the wholesale production of mesh bags has undergone various screening and processing, and the process is gradually becoming better. Today's polypropylene mesh bags are more durable and environmentally friendly. Fullway To help customers enhance their brand image, they can negotiate wholesale mesh bags with customized onion sacks. Can use The unique onion sack packaging design to gain better publicity for the buyer's brand.

Following the fierce competition in the market, mesh bags manufacturers are also facing unprecedented challenges. As a result, mesh bags manufacturer has changed the packaging of onion sack, improving it in terms of materials, design, and processing. Why not opt for corrugated boxes in the everyday packaging and transport of fruit and vegetables. In one way or another, both onion sacks and corrugated cardboard boxes can accommodate vegetables and fruit. They can be used as outer packaging for vegetables and fruit.