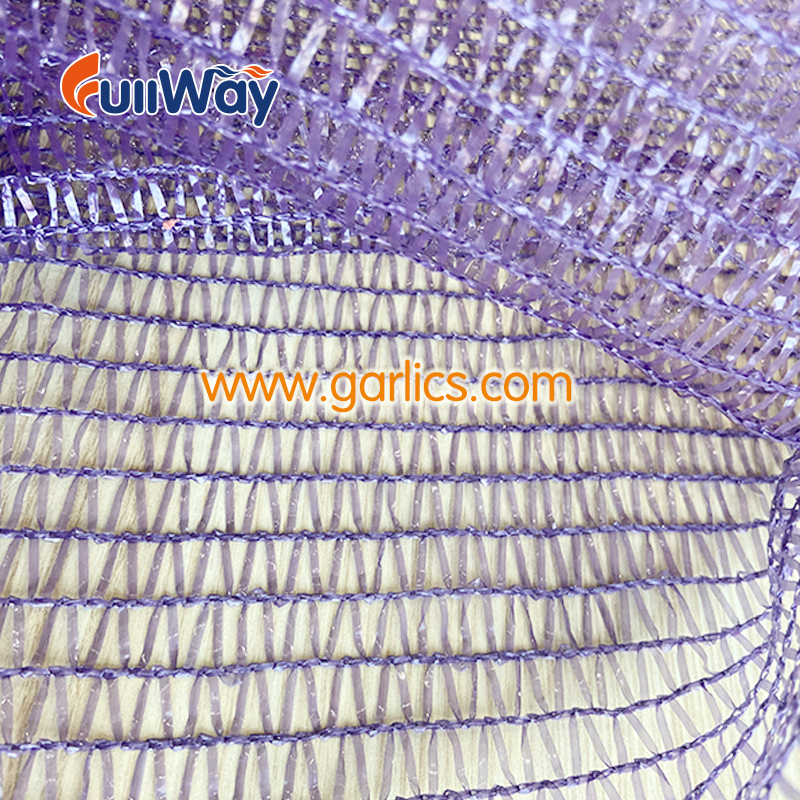

Wholesale Onion Mesh Bags

Do you still need help finding the best onion bag supplier? We are the best onion bag supplier in China. We specialize in producing high-quality and cheap onion mesh bags. The quality of all onion mesh bags sold on our website is the best. We offer a wide selection of mesh onion bags wholesale. Onion mesh bag prices range from $0.03 to $0.35 for you to choose from. Farmers and shipping companies can buy wholesale onion mesh bags on our website. They can decide to try them out there.